FACILITIES

Our

Facilities

Fabrication

We specialize in delivering high-quality fabrication processes for manufacturing various metal components and machine parts under controlled workshop conditions. The metal products we produce are crafted using advanced machinery and modern fabrication techniques.

With a complete in-house setup—including CNC bending, punching, welding, and riveting—we are equipped to manufacture a wide range of sheet metal components. Our capabilities support industries such as home appliances, trolleys, perforated sheet products, elevator and escalator parts, control panels, security system components, electronic assemblies, refrigeration, HVAC, medical equipment, pharmaceutical machinery, and many more.

Our manufacturing scope covers a broad spectrum of sheet metal fabrication and component production.

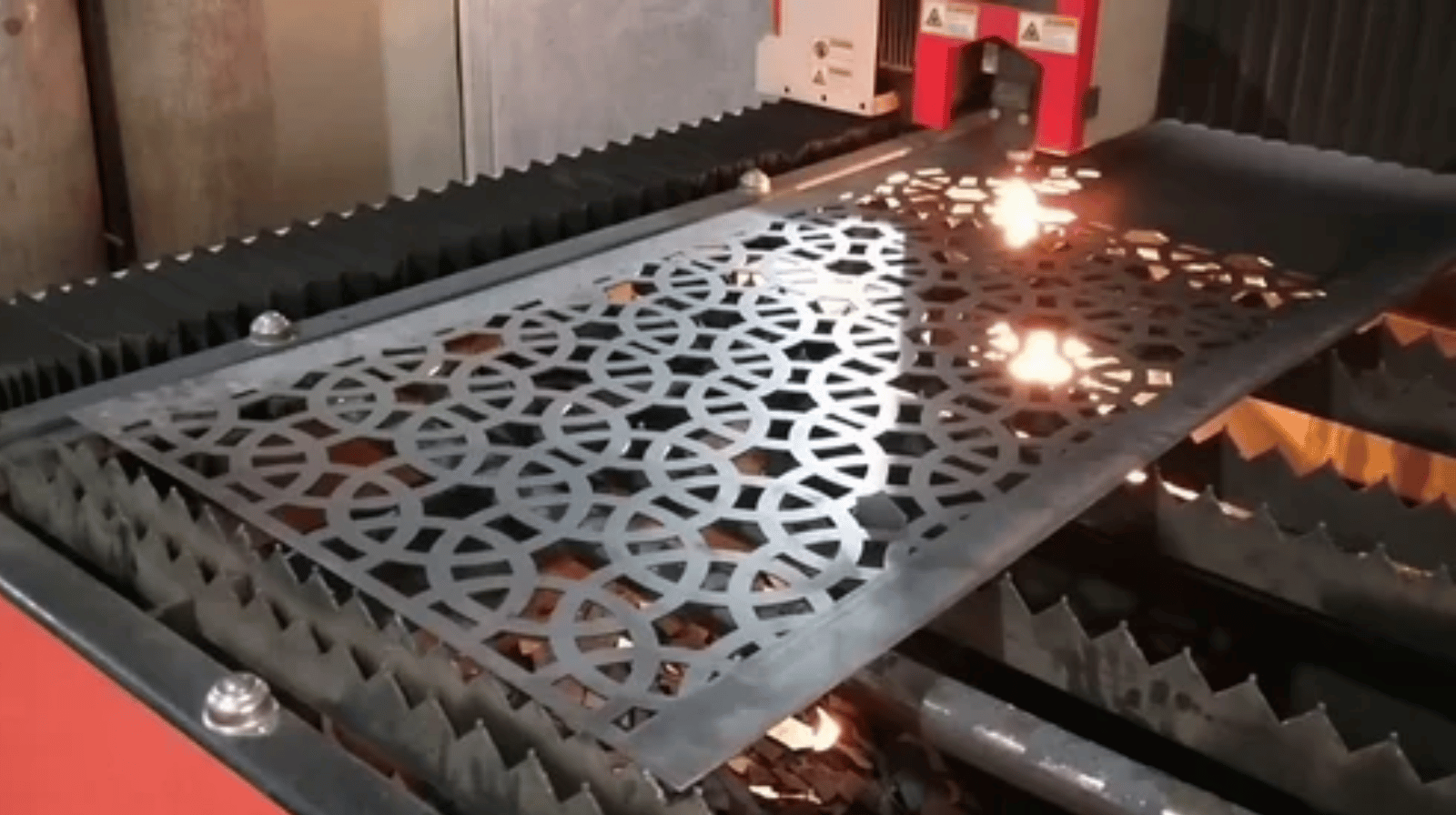

Laser Cutting

Our high-efficiency laser cutting system delivers smooth, accurate, and burr-free cuts, making it ideal for intricate profiles and large-volume production.

Cutting Capacity

-

Mild Steel (MS): Up to 16 mm

-

Stainless Steel (SS): Up to 8 mm

-

Brass: Up to 4 mm

-

Aluminium: Up to 5 mm

Highlights

-

Excellent precision with consistent repeatability

-

Fast turnaround suitable for urgent and bulk orders

-

Easily handles complex shapes and custom-designed profiles

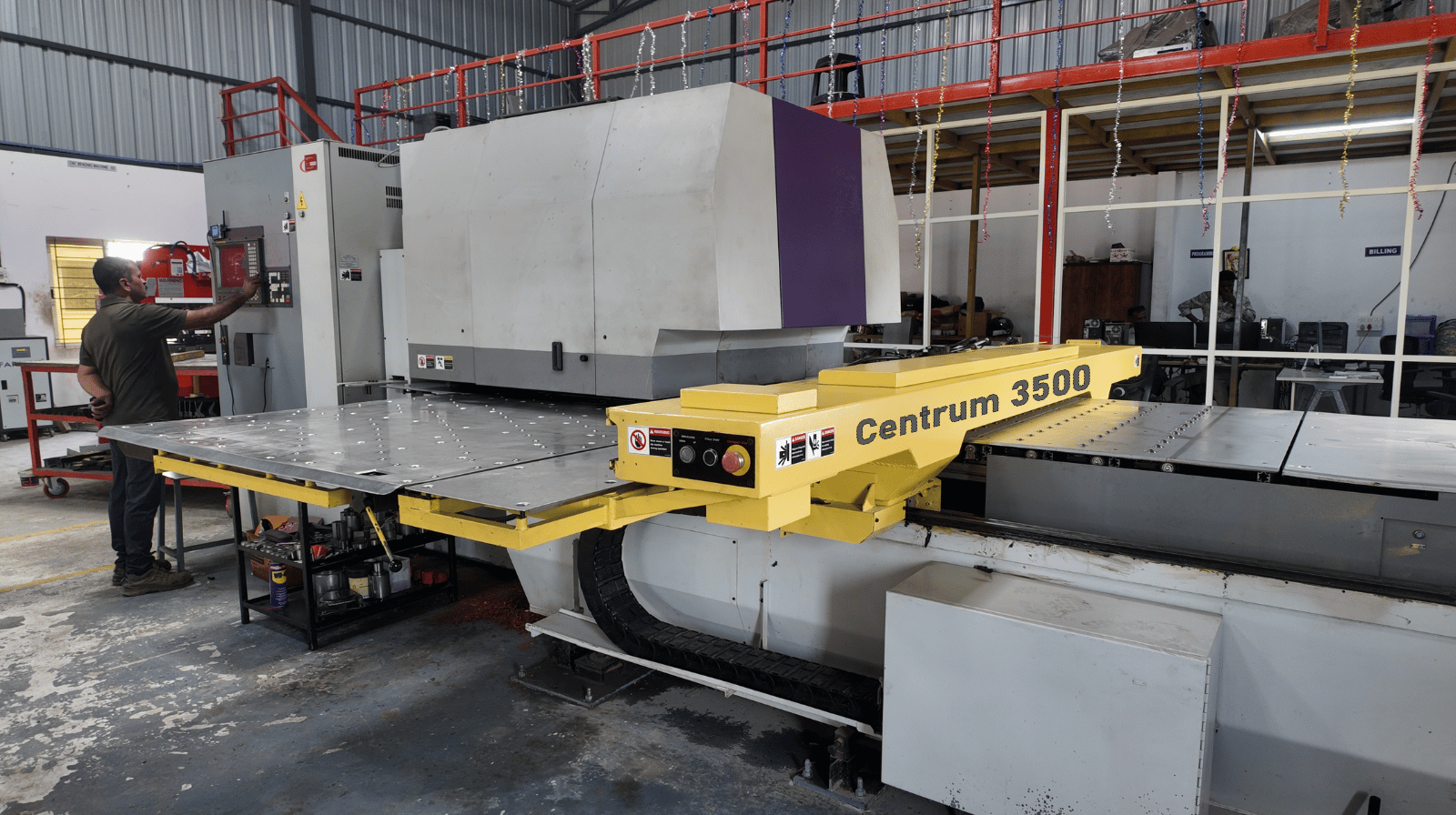

CNC Punching

Yash Technologies delivers precision-driven CNC punching job work backed by strong design expertise. Our team transforms customer drawings into highly optimized punch programs that reduce material waste while improving part accuracy. With CAD/CAM-enabled designing, we ensure every component meets exact dimensional, profile, and tolerance demands for OEMs, industrial manufacturers, and custom fabrication projects.

Quality You Can Trust

Quality is at the core of every punching operation we handle. Using advanced CNC punching machines, we maintain uniform hole accuracy, burr-free edges, and consistent repeatability across bulk production. Every job undergoes thorough inspection, ensuring compliance with industry standards and customer-specific quality parameters for long-lasting, reliable performance.

CNC Bending

Yash Technologies delivers high-precision CNC bending services supported by expert design and programming capabilities. Our team evaluates bend sequences, tooling selection, and material behavior to create accurate CAD/CAM bend programs. This ensures every component—whether simple or complex—achieves perfect angles, consistent dimensions, and minimal deformation, making it ideal for OEM production and custom fabrication requirements.

Quality You Can Trust

Quality is central to every bending job we execute. With advanced press brakes and skilled operators, we maintain tight tolerances, uniform bends, and repeatable accuracy across small and bulk batches. Each part undergoes dimensional inspection and angle verification to ensure flawless fit, strength, and finish. Yash Technologies guarantees reliable, consistent, and industry-standard quality for all CNC-bent components.

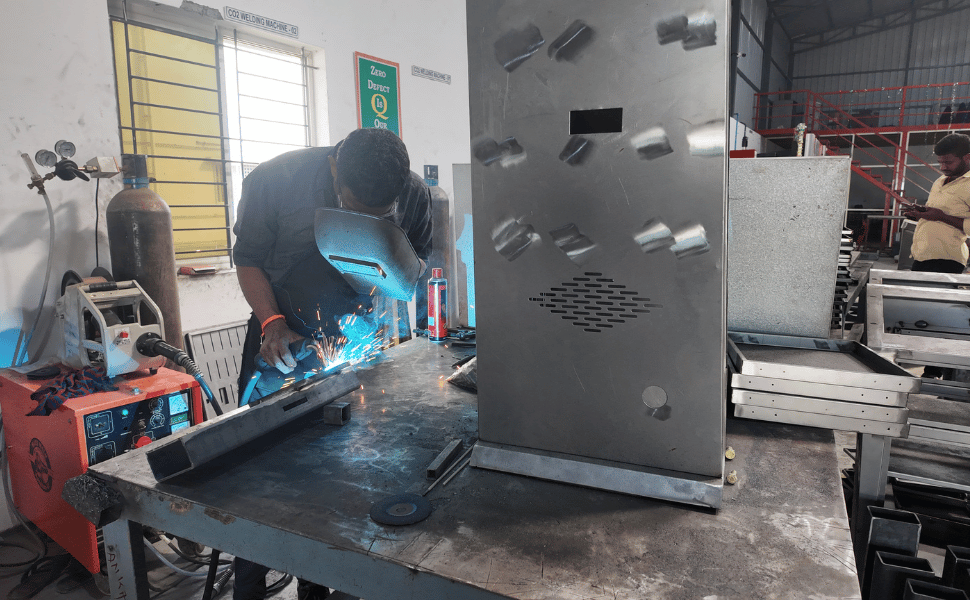

Welding & Riviting

• Stainless Fabrication/Welding

• Aluminum Fabrication/Welding

• Wrought Iron

• Ornamental Iron and entrances

• Fences

• Stair riser Fab and installation

• Certified Welding Services And much more….

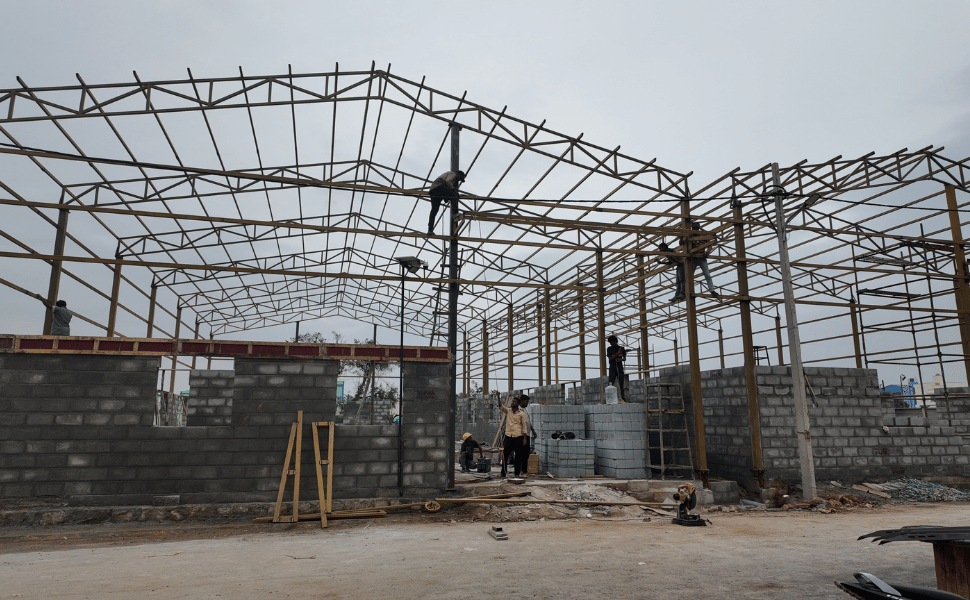

Structure Works

Yash Technologies specializes in PEB (Pre-Engineered Building) structure job works with a strong focus on smart engineering and accurate design. Our team uses advanced structural design software to create optimized building layouts, load-bearing frameworks, and connection details that ensure durability and material efficiency. From industrial sheds to warehouses and heavy-duty fabrication structures, every project is engineered with precise calculations, 3D modeling, and custom design parameters tailored to client needs.

Quality You Can Trust

Quality is embedded into every stage of our PEB structure fabrication and assembly process. We follow stringent welding, fabrication, and alignment standards to ensure every beam, column, and support member meets exact structural requirements. Each component undergoes inspection for dimensions, strength, and finish, ensuring long-term performance, safety, and weather resistance. Yash Technologies guarantees reliable, high-strength, and professionally executed PEB structure work for industrial and commercial applications.

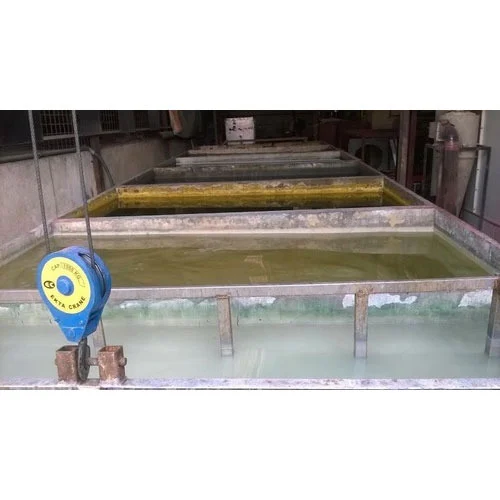

7 Tank Process Powder Coating

Complete Seven-Tank Pre-Treatment for Perfect Finish

The seven-tank process is one of the most reliable surface pre-treatment methods used to achieve strong adhesion and a flawless powder-coated finish. Each stage—from degreasing and derusting to phosphating and thorough rinsing—removes oil, rust, and impurities while preparing the metal surface for uniform coating. By following this systematic, chemical-based treatment, we ensure that every component receives a smooth, clean, and well-prepared surface before entering the powder coating booth.

Quality That Ensures Durability and Long-Lasting Performance

Quality is the core of our powder coating job work. The seven-tank process enhances corrosion resistance, improves coating strength, and ensures that the final finish remains durable even under harsh industrial conditions. After coating, components undergo curing at precise temperatures, resulting in a hard, scratch-resistant, and aesthetically superior finish. This proven method guarantees long life, consistent shine, and a premium-quality surface suitable for OEMs, fabrication industries, and outdoor applications.